PAEC JSA Blank Form 2003-2026 free printable template

Show details

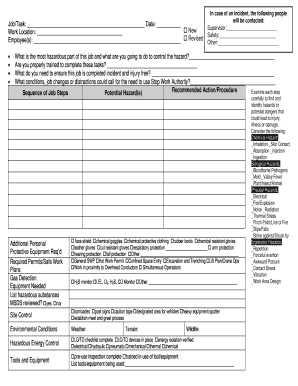

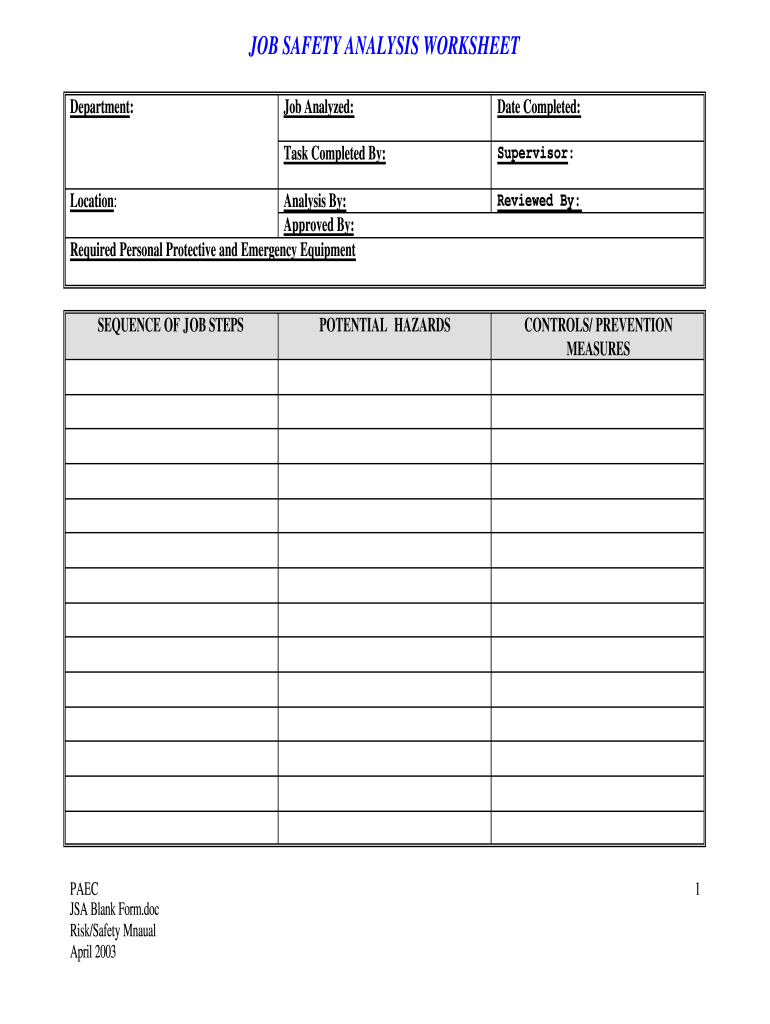

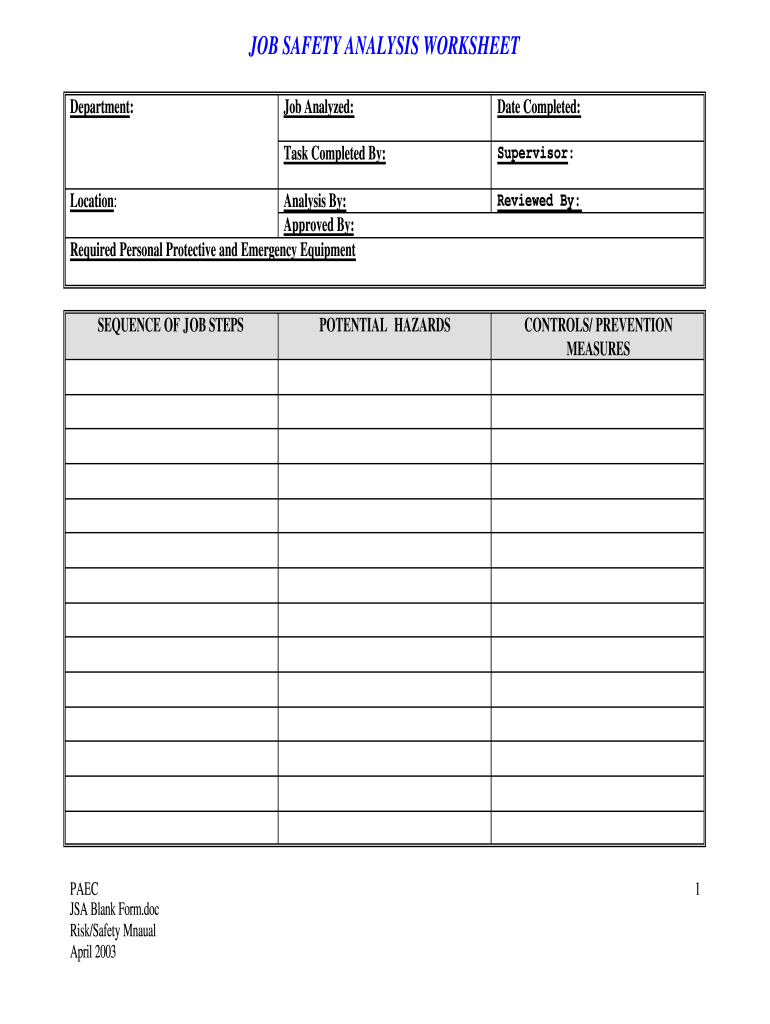

JOB SAFETY ANALYSIS WORKSHEET Department Job Analyzed Date Completed Task Completed By Supervisor Location Analysis By Approved By Required Personal Protective and Emergency Equipment SEQUENCE OF JOB STEPS PAEC JSA Blank Form.doc Risk/Safety Mnaual April 2003 POTENTIAL HAZARDS Reviewed By CONTROLS/ PREVENTION MEASURES Worksheet Location of Job or Task Employee performing Job or Task 1. Job or Task title 2. Training required to complete job/task 3. Detailed description of job as currently...

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign job safety analysis template form

Edit your jsa form template form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your jsa template form via URL. You can also download, print, or export forms to your preferred cloud storage service.

How to edit jsa pdf online

To use our professional PDF editor, follow these steps:

1

Log into your account. If you don't have a profile yet, click Start Free Trial and sign up for one.

2

Prepare a file. Use the Add New button to start a new project. Then, using your device, upload your file to the system by importing it from internal mail, the cloud, or adding its URL.

3

Edit jsa template word form. Add and replace text, insert new objects, rearrange pages, add watermarks and page numbers, and more. Click Done when you are finished editing and go to the Documents tab to merge, split, lock or unlock the file.

4

Get your file. Select the name of your file in the docs list and choose your preferred exporting method. You can download it as a PDF, save it in another format, send it by email, or transfer it to the cloud.

It's easier to work with documents with pdfFiller than you could have ever thought. Sign up for a free account to view.

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out job safety analysis in construction pdf form

How to fill out PAEC JSA Blank Form

01

Begin by downloading the PAEC JSA Blank Form from the official website or obtain it from your supervisor.

02

Fill in the date at the top of the form.

03

Write down the project or task name for which the JSA is being completed.

04

Identify and list all the job steps involved in the project or task.

05

For each step, assess the potential hazards and document them.

06

Propose control measures for each identified hazard to reduce risk.

07

Assign responsibilities for implementing the control measures.

08

Review the completed form with team members to ensure understanding and compliance.

09

Finalize the form by having it signed by all relevant parties.

Who needs PAEC JSA Blank Form?

01

Employees working on high-risk tasks or projects.

02

Supervisors and managers overseeing safety practices.

03

Safety officers and compliance personnel.

04

Contractors and subcontractors involved in the project.

05

Any team members who need to understand the risks and safety measures associated with their work.

Fill

job safety analysis template pdf

: Try Risk Free

What is form jsa?

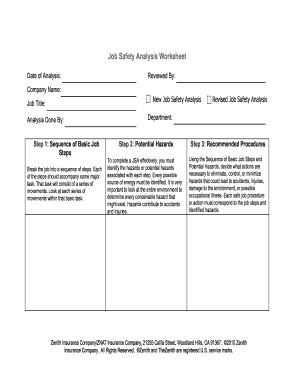

This generic JSA template, or job safety analysis form, can be used by a supervisor or safety official to analyze hazards associated with performing a certain job. Begin by filling out information about the job and employee participating in the inspection. ... Preview a completed JSA example report conducted with iAuditor.

People Also Ask about get jsa forms online

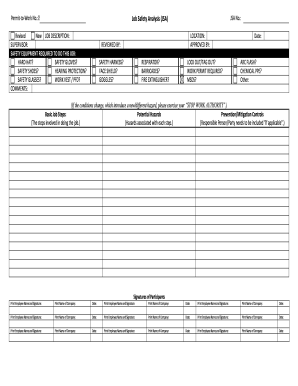

What is JSA as per OSHA?

Job Safety Analysis (JSA) In a JSA, each basic step of the job is analyzed to identify potential hazards and to recommend the safest way to do the job. Other terms used to describe this procedure are job hazard analysis (JHA) and job hazard breakdown.

How many steps are in a completed JSA?

The process of creating a job safety analysis report is generally broken down into four steps, which makes it easier to ensure you complete every portion of the requirements a reap the benefits a JSA offers.

What is a JSA form?

It is a systematic examination and documentation of every task within each job to identify health and safety hazards, and the steps to control each task. Job Safety Analysis (JSA) Fact Sheet. Job Safety Analysis (JSA) Form.

How do I fill out JSA?

A Breakdown of the 4 Steps of a Job Safety Analysis (JSA) Choose a job to analyze. At some point you would ideally do a JSA for every job performed in your workplace. Break the job down into specific tasks. Determine hazards and risk present in each task. Identify preventative controls and residual risk.

What is a JSA vs Jha?

What is a job hazard analysis? A job hazard analysis (JHA), also called a job safety analysis (JSA), is a technique to identify the dangers of specific tasks in order to reduce the risk of injury to workers.

What are the 3 steps to a JSA?

A Breakdown of the 4 Steps of a Job Safety Analysis (JSA) Choose a job to analyze. At some point you would ideally do a JSA for every job performed in your workplace. Break the job down into specific tasks. Determine hazards and risk present in each task. Identify preventative controls and residual risk.

What is JSA simple definition?

What is a Job Safety Analysis? A job safety analysis (JSA) is a procedure which helps integrate accepted safety and health principles and practices into a particular task or job operation. In a JSA, each basic step of the job is to identify potential hazards and to recommend the safest way to do the job.

What order are the three steps in the JSA completed?

Step by Step Guide to Job Safety and Job Hazard Analysis Step 1: Choose the Procedure. The first step in performing a JSA is to identify which procedures you'll focus on. Step 2: Break the Job Into Steps. Step 3: Identify Hazards. Step 4: Implement Solutions. Step 5: Communicate the Findings. Step 6: Review and Update.

What is a JSA and when is it used?

Job Safety Analysis (JSA) is a safety tool that can be used to define and control hazards associated with a certain process, job, or procedure. It is a systematic examination and documentation of every task within each job to identify health and safety hazards, and the steps to control each task.

Our user reviews speak for themselves

Read more or give pdfFiller a try to experience the benefits for yourself

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I get jsa form template fillable?

The pdfFiller premium subscription gives you access to a large library of fillable forms (over 25 million fillable templates) that you can download, fill out, print, and sign. In the library, you'll have no problem discovering state-specific jsa form pdf and other forms. Find the template you want and tweak it with powerful editing tools.

Can I create an electronic signature for the printable jsa form in Chrome?

As a PDF editor and form builder, pdfFiller has a lot of features. It also has a powerful e-signature tool that you can add to your Chrome browser. With our extension, you can type, draw, or take a picture of your signature with your webcam to make your legally-binding eSignature. Choose how you want to sign your blank jsa form and you'll be done in minutes.

How can I edit jsa forms on a smartphone?

You can easily do so with pdfFiller's apps for iOS and Android devices, which can be found at the Apple Store and the Google Play Store, respectively. You can use them to fill out PDFs. We have a website where you can get the app, but you can also get it there. When you install the app, log in, and start editing printable jsa forms, you can start right away.

What is PAEC JSA Blank Form?

The PAEC JSA Blank Form is a standardized document used for reporting and assessment related to Joint Social Accountability (JSA) measures within a specific framework, often related to employment or welfare programs.

Who is required to file PAEC JSA Blank Form?

Organizations and individuals participating in programs monitored by the PAEC (Public Accountability and Evaluation Committee) are required to file the PAEC JSA Blank Form, typically including employers and service providers.

How to fill out PAEC JSA Blank Form?

To fill out the PAEC JSA Blank Form, gather the necessary information, adhere to the provided guidelines, accurately complete all sections of the form, and ensure all data is consistent and truthful before submission.

What is the purpose of PAEC JSA Blank Form?

The purpose of the PAEC JSA Blank Form is to facilitate transparency and accountability in reporting, ensuring that relevant data is collected for the evaluation of social programs and compliance with regulatory requirements.

What information must be reported on PAEC JSA Blank Form?

The PAEC JSA Blank Form requires reporting information such as organizational details, participant demographics, program objectives, outcomes, and any other relevant data pertaining to social accountability measures implemented.

Fill out your PAEC JSA Blank Form online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Jsa Template Pdf is not the form you're looking for?Search for another form here.

Keywords relevant to jsa forms pdf

Related to jsa submission form

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.